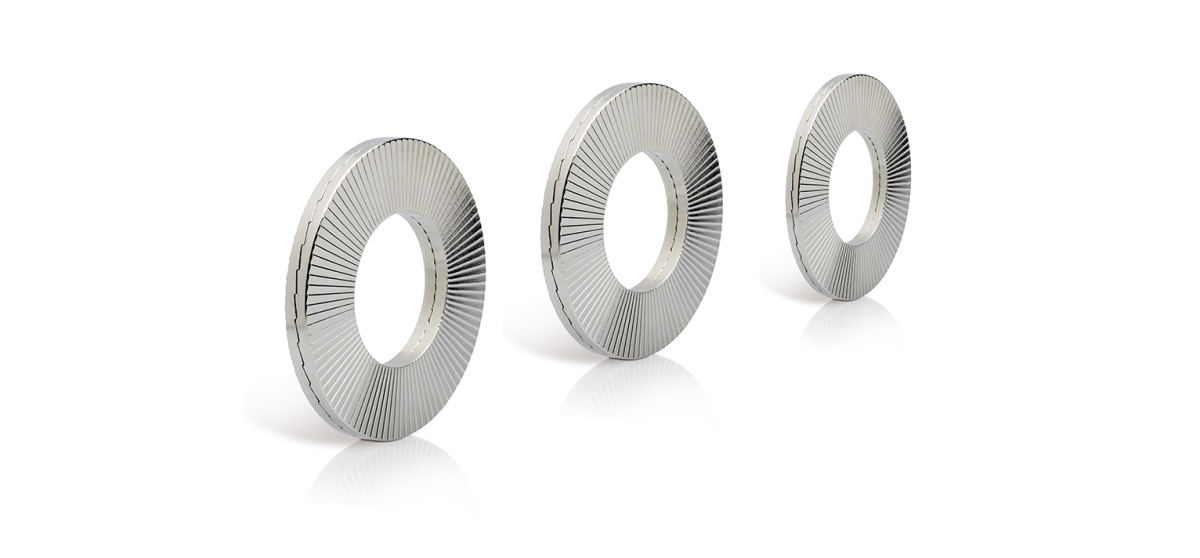

Wedge lock washers

With wedge lock washers, we offer a high-quality locking system for sophisticated screw connections, which also offers reliable locking against unscrewing, even under extreme vibrations or dynamic stresses, thus guaranteeing maximum safety for you!

In so doing, we not only rely on sophisticated quality controls, but also subject the products to external and objective quality tests according to prescribed testing procedures.

Advantages:

- Locks against unscrewing, with both higher and lower pretensioning

- Particularly for dynamic stresses - including when lubricants are used

- Can be used repeatedly with no loss of quality or comfort

- Very easy mounting and removal (wedge lock washers are already bonded in pairs)

- Even for high-strength screws 8.8, 10.9 and 12.9 and the corresponding nuts

- In steel or stainless steel - other materials are available on request

- With narrow and wide contact surfaces

Materials and technical properties:

Stainless steel design A4, 1.4404, surface-hardened > 520 HV0.05

- Steel design, through-hardened, 460-560 HV1

- Surface zinc flake coating Delta-Protect KL 100 + slide coating VH302, 600 hours

- Special materials: Inconel 718 or 254SMO (1.4547) possible on request

- Note: In order to ensure that a lock to prevent unscrewing works properly, the hardness of the mating material must be lower than that of the washer.

Wedge lock washers meet the requirements of a screw fastener due to their geometry and technical properties.

The applied pretensioning is maintained as far as possible.

A maximum pretension loss of 20% is only to be expected as a result of creep and settling.

Wedge lock washers are therefore defined as locks against unscrewing.

The functional principle:

- Difference in hardness

The surface hardness of lock washers is higher than conventional screws (strength class 8.8, 10.9, 12.9).

Radial ribs on the exterior make an impression, i.e. a positive-locking connection is formed when the screw connection is tightened.

- Angle difference α > β

Wedge surface angle α between the halves of the lock washer is larger than the gradient angle β of the screw thread.

The expansion of the thickness of the lock washer is greater than the possible longitudinal displacement of the screw along the thread.

- Friction difference μo > μi

Wedge sections on the joint faces of the two halves of the washer have a considerably lower coefficiency of friction ûi than the toothed exterior ûo of the washer.

An unscrewing movement (caused by dynamic stresses) always causes movement between the two halves of the washer.

- Pretensioning difference Fdyn > Fstat

The expansion of the thickness of the lock washer caused by unscrewing movement causes the screw to elongate.

This results in an increase in pretensioning, causing the screw to self-lock.